LM8040-GSV12-FL1

Longmem

40"x7.9"x1.125"

15kg

Carton, OEM/ODM

7-14 days

ISO9001,ISO50001,GJB9001C,EAC,HALA,NSF

Accept

Air Dryers, Carbon Dioxide Removal ,New Energy Industry and etc.

| Availability: | |

|---|---|

A gas separation membrane element is a key component used in gas separation processes, such as nitrogen generation, carbon dioxide removal, and oxygen enrichment. It consists of a membrane material that has selective permeability to certain gases.

The membrane is typically made of polymers or ceramic materials with specific properties that allow the preferential passage of certain gases based on their molecular size or affinity. The membrane element is designed in a way that maximizes the surface area available for gas separation while maintaining structural integrity.

When a mixed gas stream passes through the membrane element, different gases are separated into two streams: permeate and retentate. The permeate stream contains the purified or enriched gas that has successfully passed through the membrane, while the retentate stream contains the remaining impurities or depleted gases.

Gas separation membrane elements find applications in various industries including petrochemicals, food and beverage production, pharmaceuticals, and electronics manufacturing. They offer advantages such as low energy consumption, compact size, continuous operation, and environmental friendliness compared to traditional gas separation methods like cryogenic distillation or adsorption processes.

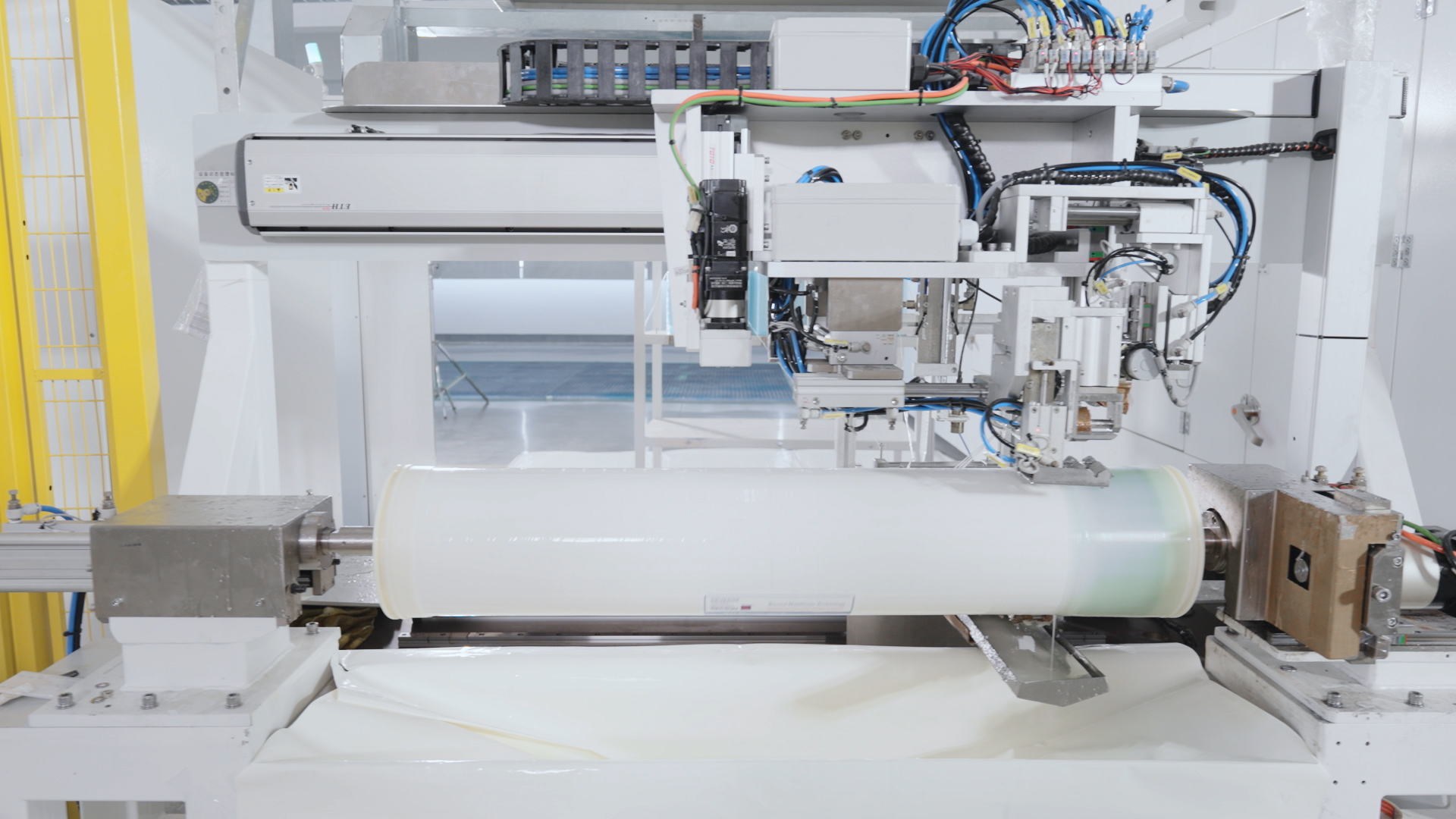

The LM8040-GSV12-FL1 gas separation membrane element, the exact manufacturing process of this specific membrane element may not be publicly disclosed, as it likely involves proprietary technologies and methods.

However, in general, the manufacturing process for gas separation membrane elements involves several steps:

Membrane materials with suitable properties for the desired gas separation are chosen. This could include polymers such as polyimides or polymeric blends, or ceramic materials.

The selected membrane material is prepared and cast onto a suitable support material or substrate. This can be done through various techniques like solution casting, phase inversion, or electrospinning.

The membrane surface may undergo treatments to enhance its performance and durability. For example, it may undergo chemical modification or coating to improve selectivity or resistance to fouling.

Multiple layers of the prepared membranes are assembled into a module structure that allows for efficient gas separation while ensuring mechanical stability and integrity.

The module is sealed to prevent leakage and connected to appropriate inlet/outlet ports for the feed gas stream.

Each manufactured membrane element undergoesrigorous testing to ensure its performance meets the desired specifications. This can include tests for gas permeability, selectivity, pressure drop, and structural integrity.

It is important to note that the specific manufacturing process may vary depending on the type of gas separation membrane element and the manufacturer. Additionally, companies like Membrane Solutions may have their own unique processes and technologies for producing their products.

Longmem S-VOCs membrane uses a polymer composite membrane with excellent selectivity for organic solvents. The membrane preferentially transmits large molecules of VOCs such as hydrocarbons.

The VOCs that can be recovered by the Longmem S-VOCs membrane separation method include aliphatic and aromatic hydrocarbons, chlorinated hydrocarbons, ketones, nitriles, phenols, alcohols, amines, chlorofluorocarbons, etc., such as butane, octane , trichlorethylene, acetone, styrene, acetonitrile, methyl chloride, methyl isobutyl ketone, methylene chloride, chloroform, gasoline, toluene, methane, carbon tetrachloride, methanol, ethylene oxide, propylene oxide , CFC-11, HCFC-12, etc.

For the membrane organic gas recovery process, the separation selectivity of the membrane is achieved through the difference in the permeability rate of each component (VOCs, nitrogen, oxygen, carbon dioxide, etc.) through the membrane. Dissolution and adsorption play a decisive role, and the VOCs components Always penetrated first. This achieves the purpose of separation of VOCs and nitrogen vapor and recovery of oil vapor.

Longmem S-VOCs is a multi-layer composite structure that uses a non-traditional film-forming process. Composite structure. The top organophilic layer and the support layer are covalently bonded, which greatly increases the service life of the membrane and has excellent solvent swelling resistance and separation and concentration coefficient.

The LM8040-GSV12-FL1 gas separation membrane element offers high selectivity, allowing it to effectively separate specific gases from a mixed gas stream. This makes it suitable for various applications such as nitrogen generation, oxygen enrichment, and carbon dioxide removal.

The membrane element is designed to provide excellent performance in terms of gas separation efficiency and productivity. It can deliver high purity gases with low impurity levels, ensuring reliable and consistent results.

The LM8040-GSV-FL1 membrane element features a compact design, making it suitable for installations where space is limited. Its small footprint allows for easy integration into existing systems or the construction of new compact gas separation units.

Gas separation processes using this membrane element lower energy consumption compared to other traditional methods such as cryogenic distillation or pressure swing adsorption (PSA). This not only reduces operating costs but also minimizes the environmental impact by reducing carbon emissions.

The LM8040-GSV12-FL1 membrane element is designed for long-term durability and reliability. It has excellent chemical resistance properties that allow it to withstand harsh operating conditions without degradation or loss of performance over time.

The membrane element is designed for ease of installation and maintenance, with standard industry connectors that facilitate quick and hassle-free integration into existing systems. Additionally, its modular design allows for easy replacement of individual elements if needed, minimizing downtime during maintenance activities.

Overall, the LM8040-GSV12-FL1 gas separation membrane element offers numerous advantages including high selectivity, excellent performance, compactness, energy efficiency, long lifespan,and ease of installation/maintenance.This makes it an ideal choice for various industrial applications requiring efficient gas separation processes.

The LM8040-GSV12-FL1 gas separation membrane element can be applied in various industries and applications, including:

The membrane element can be used for the separation of hydrogen and carbon dioxide from natural gas streams. This helps in enhancing the purity of the natural gas and reduces the impurities that can damage equipment or reduce the energy value of natural gas.

The membrane element can be used for the removal of hydrogen sulfide (H2S) from refinery gases. This is important as H2S is a and corrosive impurity that needs to be removed for safety reasons.

The membrane element can be utilized to upgrade biogas by separating out carbon dioxide (CO2) and other impurities, resulting in higher-purity methane (CH4). This makes it suitable for use as a renewable energy source or as a substitute for natural gas.

The membrane element can also be used to separate oxygen (O2) from air streams. This is useful in applications such as medical oxygen generation or industrial processes where high-purity oxygen is required.

The LM8040-GSV12-FL1 membrane element can selectively separate hydrogen molecules from mixed gas streams, making it suitable for recovering and purifying hydrogen in various industries like chemical production, electronics manufacturing, fuel cell technology, etc.

These are just a few examples of where LM8040-GSV12-FL1 gas separation membranes could be applied; however, there might be other specific applications depending on individual requirements within different industries.

While the LM8040-GSV12 Gas Separation Membrane Element is a highly efficient and reliable product, there are a few warnings and considerations to keep in mind:

It is crucial to install the membrane element correctly, following the manufacturer's guidelines and instructions. Improper installation can lead to reduced performance or damage to the membrane.

The quality of the feed water should be within the recommended limits specified by the manufacturer. High levels of suspended solids, organic matter, chlorine, or other contaminants can potentially damage or foul the membrane.

Brackish water contains various minerals and salts that can accumulate on the surface of the membrane over time, leading to fouling or scaling issues. Regular maintenance and cleaning procedures should be implemented to prevent these problems.

It is important to ensure that the membrane element is compatible with the chemicals used in the feed water or cleaning solutions. Some chemicals may degrade or damage the membrane, leading to reduced performance or premature failure.

The membrane element should be operated within the recommended pressure and temperature limits specified by the manufacturer. Operating outside of these limits can negatively impact performance and longevity.

Proper maintenance is essential for optimal performance and longevity of the membrane element. This includes routine cleaning, monitoring of operating parameters, and replacement of worn-out parts as necessary.

If you are unsure about any aspect of installing, operating, or maintaining the LM4040-BW Brackish Water Reverse Osmosis Membrane Element, it is recommended to seek professional assistance from a qualified technician or water treatment specialist.

By following these warnings and guidelines, you can maximize the lifespan and efficiency of your brackish water reverse osmosis membrane elements.

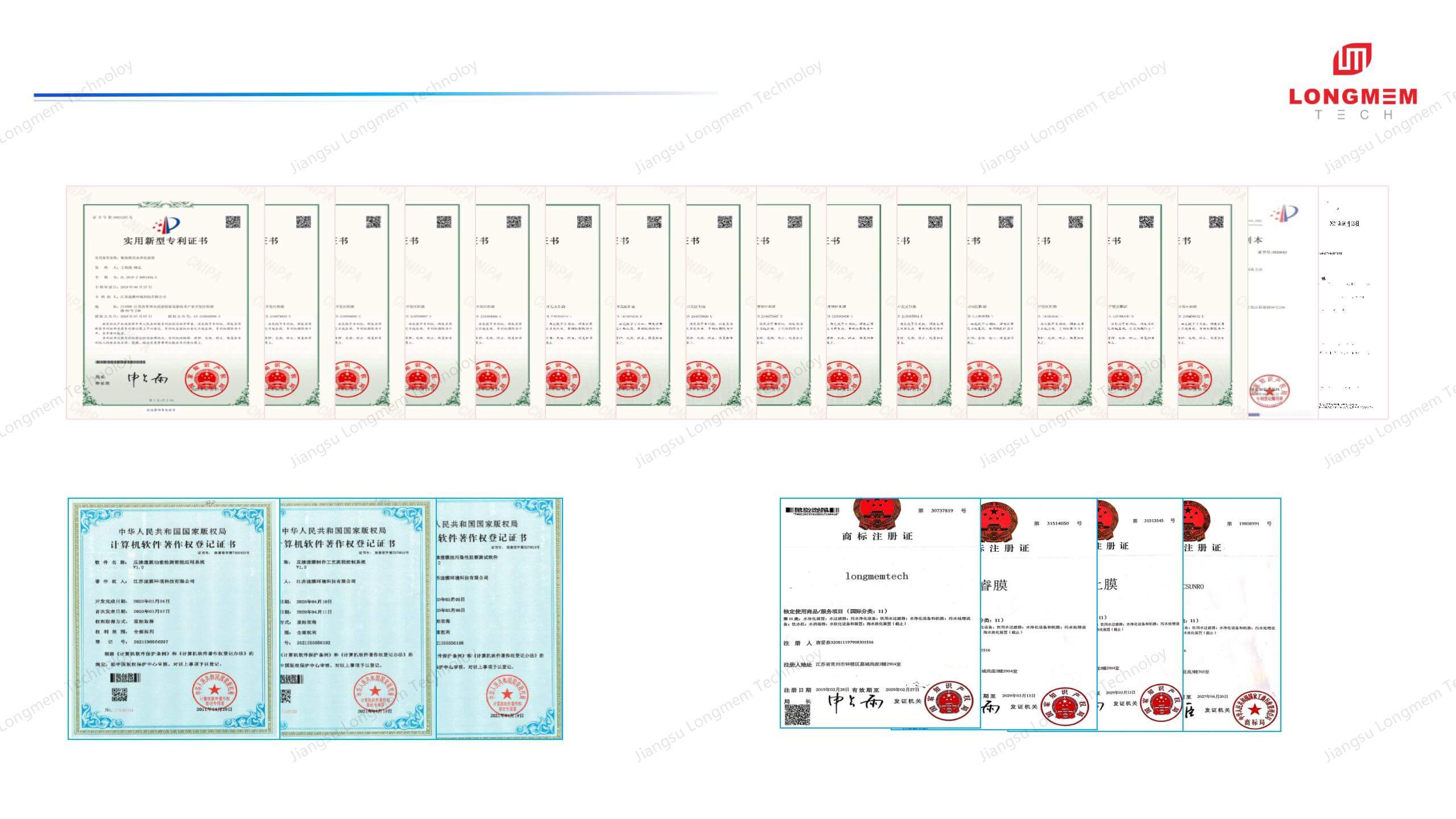

There are several reasons why you choose to cooperate with Jiangsu Longmem Technology Co., Ltd.:

Jiangsu Longmem Technology Co., Ltd. has a wealth of experience in the industry specialied in water treatment technologies and solutions. They have a team of experts who possess extensive knowledge and expertise in their field.

The company is known for its advanced technological solutions for water treatment, including membrane filtration systems, reverse osmosis, and other cutting-edge technologies. By cooperating with them, one can benefit from state-of-the-art equipment and solutions.

Jiangsu Longmem Technology Co., Ltd. offers customized solutions tailored to the specific needs of their clients. They take into account various factors such as water quality, quantity, and budget constraints to provide effective and efficient solutions.

The company is committed to providing high-quality products and services to its customers. They adhere to strict quality control measures throughout the production process, ensuring that their products meet international standards.

Jiangsu Longmem Technology Co., Ltd.'s customer support team is dedicated to providing prompt assistance and after-sales services to their clients around the world. This ensures that any issues or concerns are addressed promptly.

The company has built a strong reputation in the industry for delivering reliable water treatment solutions over many years of operation.

Overall, by choosing to cooperate with Jiangsu Longmem Technology Co., Ltd., one can access their expertise, advanced technologies, customized solutions, high-quality products/services along with excellent customer support—all factors contributing towards successful collaboration in achieving efficient water treatment goals.

Jiangsu Longmem Technology Co., Ltd., is top 3 membrane element manufacturer in China.

Yes , you can have Jiangsu Longmem Technology Co., Ltd. sample for starting the business , but it is not free.

Please contact Logmem team for detail .

A gas separation membrane element is a key component used in gas separation processes, such as nitrogen generation, carbon dioxide removal, and oxygen enrichment. It consists of a membrane material that has selective permeability to certain gases.

The membrane is typically made of polymers or ceramic materials with specific properties that allow the preferential passage of certain gases based on their molecular size or affinity. The membrane element is designed in a way that maximizes the surface area available for gas separation while maintaining structural integrity.

When a mixed gas stream passes through the membrane element, different gases are separated into two streams: permeate and retentate. The permeate stream contains the purified or enriched gas that has successfully passed through the membrane, while the retentate stream contains the remaining impurities or depleted gases.

Gas separation membrane elements find applications in various industries including petrochemicals, food and beverage production, pharmaceuticals, and electronics manufacturing. They offer advantages such as low energy consumption, compact size, continuous operation, and environmental friendliness compared to traditional gas separation methods like cryogenic distillation or adsorption processes.

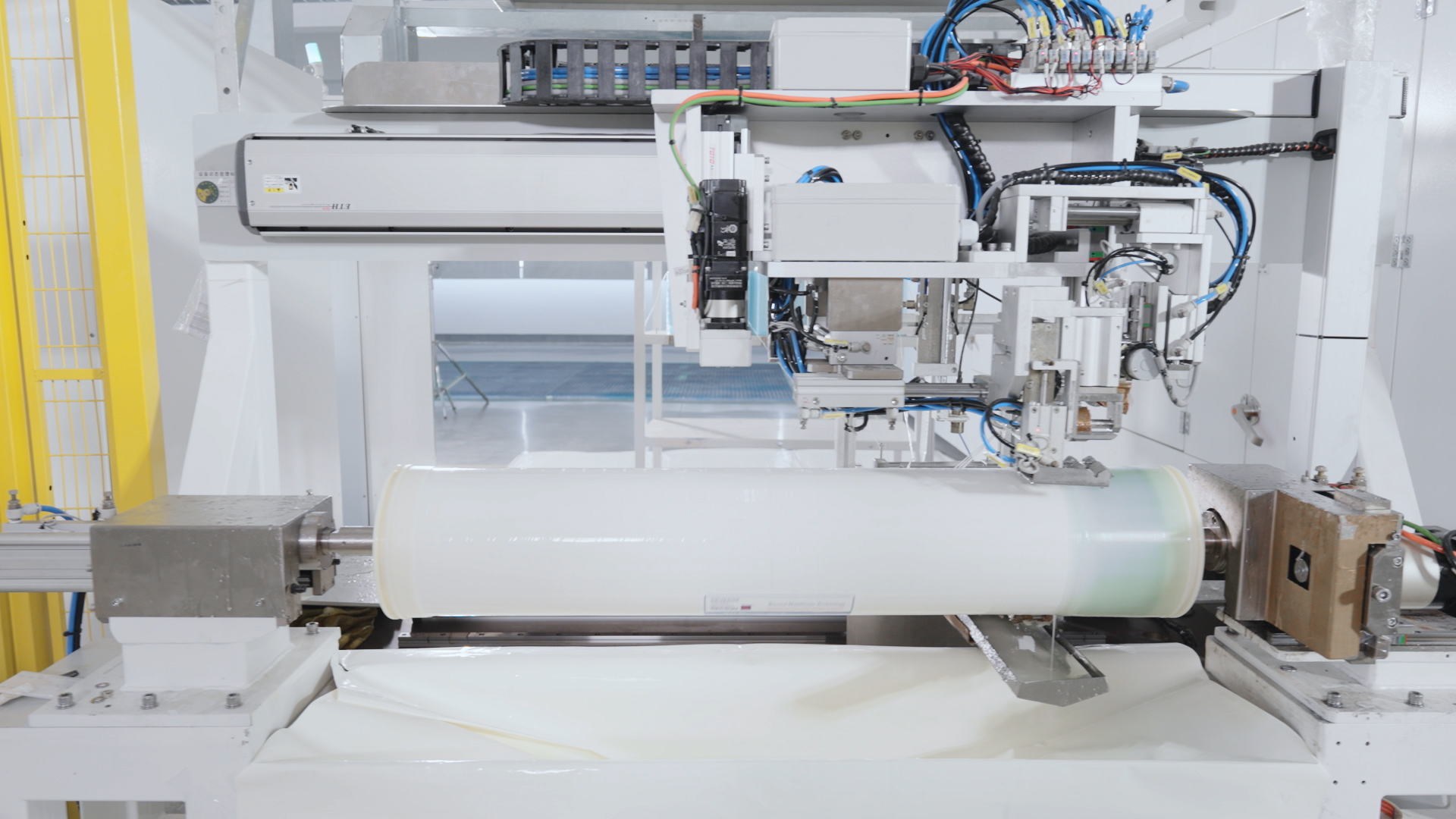

The LM8040-GSV12-FL1 gas separation membrane element, the exact manufacturing process of this specific membrane element may not be publicly disclosed, as it likely involves proprietary technologies and methods.

However, in general, the manufacturing process for gas separation membrane elements involves several steps:

Membrane materials with suitable properties for the desired gas separation are chosen. This could include polymers such as polyimides or polymeric blends, or ceramic materials.

The selected membrane material is prepared and cast onto a suitable support material or substrate. This can be done through various techniques like solution casting, phase inversion, or electrospinning.

The membrane surface may undergo treatments to enhance its performance and durability. For example, it may undergo chemical modification or coating to improve selectivity or resistance to fouling.

Multiple layers of the prepared membranes are assembled into a module structure that allows for efficient gas separation while ensuring mechanical stability and integrity.

The module is sealed to prevent leakage and connected to appropriate inlet/outlet ports for the feed gas stream.

Each manufactured membrane element undergoesrigorous testing to ensure its performance meets the desired specifications. This can include tests for gas permeability, selectivity, pressure drop, and structural integrity.

It is important to note that the specific manufacturing process may vary depending on the type of gas separation membrane element and the manufacturer. Additionally, companies like Membrane Solutions may have their own unique processes and technologies for producing their products.

Longmem S-VOCs membrane uses a polymer composite membrane with excellent selectivity for organic solvents. The membrane preferentially transmits large molecules of VOCs such as hydrocarbons.

The VOCs that can be recovered by the Longmem S-VOCs membrane separation method include aliphatic and aromatic hydrocarbons, chlorinated hydrocarbons, ketones, nitriles, phenols, alcohols, amines, chlorofluorocarbons, etc., such as butane, octane , trichlorethylene, acetone, styrene, acetonitrile, methyl chloride, methyl isobutyl ketone, methylene chloride, chloroform, gasoline, toluene, methane, carbon tetrachloride, methanol, ethylene oxide, propylene oxide , CFC-11, HCFC-12, etc.

For the membrane organic gas recovery process, the separation selectivity of the membrane is achieved through the difference in the permeability rate of each component (VOCs, nitrogen, oxygen, carbon dioxide, etc.) through the membrane. Dissolution and adsorption play a decisive role, and the VOCs components Always penetrated first. This achieves the purpose of separation of VOCs and nitrogen vapor and recovery of oil vapor.

Longmem S-VOCs is a multi-layer composite structure that uses a non-traditional film-forming process. Composite structure. The top organophilic layer and the support layer are covalently bonded, which greatly increases the service life of the membrane and has excellent solvent swelling resistance and separation and concentration coefficient.

The LM8040-GSV12-FL1 gas separation membrane element offers high selectivity, allowing it to effectively separate specific gases from a mixed gas stream. This makes it suitable for various applications such as nitrogen generation, oxygen enrichment, and carbon dioxide removal.

The membrane element is designed to provide excellent performance in terms of gas separation efficiency and productivity. It can deliver high purity gases with low impurity levels, ensuring reliable and consistent results.

The LM8040-GSV-FL1 membrane element features a compact design, making it suitable for installations where space is limited. Its small footprint allows for easy integration into existing systems or the construction of new compact gas separation units.

Gas separation processes using this membrane element lower energy consumption compared to other traditional methods such as cryogenic distillation or pressure swing adsorption (PSA). This not only reduces operating costs but also minimizes the environmental impact by reducing carbon emissions.

The LM8040-GSV12-FL1 membrane element is designed for long-term durability and reliability. It has excellent chemical resistance properties that allow it to withstand harsh operating conditions without degradation or loss of performance over time.

The membrane element is designed for ease of installation and maintenance, with standard industry connectors that facilitate quick and hassle-free integration into existing systems. Additionally, its modular design allows for easy replacement of individual elements if needed, minimizing downtime during maintenance activities.

Overall, the LM8040-GSV12-FL1 gas separation membrane element offers numerous advantages including high selectivity, excellent performance, compactness, energy efficiency, long lifespan,and ease of installation/maintenance.This makes it an ideal choice for various industrial applications requiring efficient gas separation processes.

The LM8040-GSV12-FL1 gas separation membrane element can be applied in various industries and applications, including:

The membrane element can be used for the separation of hydrogen and carbon dioxide from natural gas streams. This helps in enhancing the purity of the natural gas and reduces the impurities that can damage equipment or reduce the energy value of natural gas.

The membrane element can be used for the removal of hydrogen sulfide (H2S) from refinery gases. This is important as H2S is a and corrosive impurity that needs to be removed for safety reasons.

The membrane element can be utilized to upgrade biogas by separating out carbon dioxide (CO2) and other impurities, resulting in higher-purity methane (CH4). This makes it suitable for use as a renewable energy source or as a substitute for natural gas.

The membrane element can also be used to separate oxygen (O2) from air streams. This is useful in applications such as medical oxygen generation or industrial processes where high-purity oxygen is required.

The LM8040-GSV12-FL1 membrane element can selectively separate hydrogen molecules from mixed gas streams, making it suitable for recovering and purifying hydrogen in various industries like chemical production, electronics manufacturing, fuel cell technology, etc.

These are just a few examples of where LM8040-GSV12-FL1 gas separation membranes could be applied; however, there might be other specific applications depending on individual requirements within different industries.

While the LM8040-GSV12 Gas Separation Membrane Element is a highly efficient and reliable product, there are a few warnings and considerations to keep in mind:

It is crucial to install the membrane element correctly, following the manufacturer's guidelines and instructions. Improper installation can lead to reduced performance or damage to the membrane.

The quality of the feed water should be within the recommended limits specified by the manufacturer. High levels of suspended solids, organic matter, chlorine, or other contaminants can potentially damage or foul the membrane.

Brackish water contains various minerals and salts that can accumulate on the surface of the membrane over time, leading to fouling or scaling issues. Regular maintenance and cleaning procedures should be implemented to prevent these problems.

It is important to ensure that the membrane element is compatible with the chemicals used in the feed water or cleaning solutions. Some chemicals may degrade or damage the membrane, leading to reduced performance or premature failure.

The membrane element should be operated within the recommended pressure and temperature limits specified by the manufacturer. Operating outside of these limits can negatively impact performance and longevity.

Proper maintenance is essential for optimal performance and longevity of the membrane element. This includes routine cleaning, monitoring of operating parameters, and replacement of worn-out parts as necessary.

If you are unsure about any aspect of installing, operating, or maintaining the LM4040-BW Brackish Water Reverse Osmosis Membrane Element, it is recommended to seek professional assistance from a qualified technician or water treatment specialist.

By following these warnings and guidelines, you can maximize the lifespan and efficiency of your brackish water reverse osmosis membrane elements.

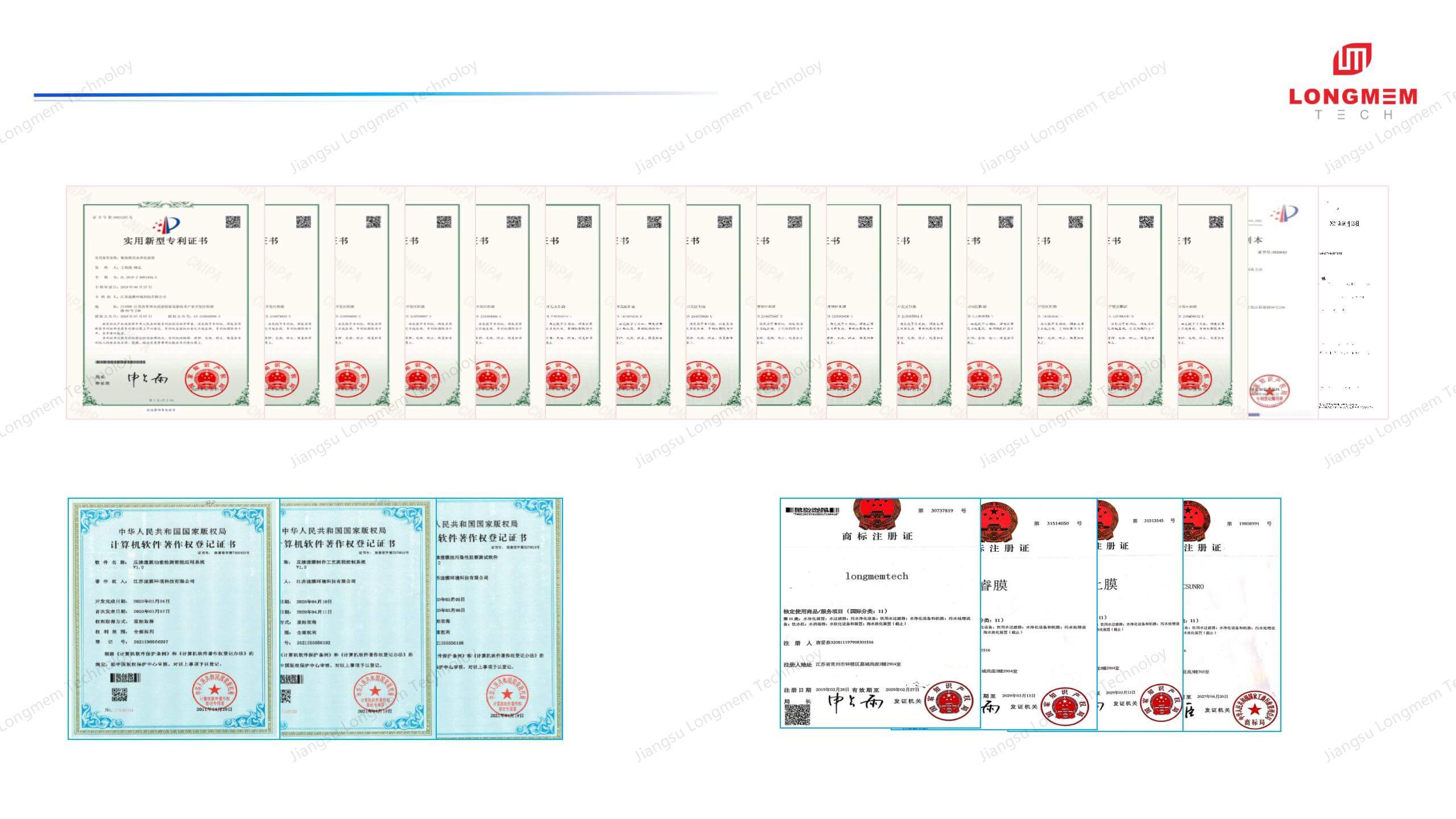

There are several reasons why you choose to cooperate with Jiangsu Longmem Technology Co., Ltd.:

Jiangsu Longmem Technology Co., Ltd. has a wealth of experience in the industry specialied in water treatment technologies and solutions. They have a team of experts who possess extensive knowledge and expertise in their field.

The company is known for its advanced technological solutions for water treatment, including membrane filtration systems, reverse osmosis, and other cutting-edge technologies. By cooperating with them, one can benefit from state-of-the-art equipment and solutions.

Jiangsu Longmem Technology Co., Ltd. offers customized solutions tailored to the specific needs of their clients. They take into account various factors such as water quality, quantity, and budget constraints to provide effective and efficient solutions.

The company is committed to providing high-quality products and services to its customers. They adhere to strict quality control measures throughout the production process, ensuring that their products meet international standards.

Jiangsu Longmem Technology Co., Ltd.'s customer support team is dedicated to providing prompt assistance and after-sales services to their clients around the world. This ensures that any issues or concerns are addressed promptly.

The company has built a strong reputation in the industry for delivering reliable water treatment solutions over many years of operation.

Overall, by choosing to cooperate with Jiangsu Longmem Technology Co., Ltd., one can access their expertise, advanced technologies, customized solutions, high-quality products/services along with excellent customer support—all factors contributing towards successful collaboration in achieving efficient water treatment goals.

Jiangsu Longmem Technology Co., Ltd., is top 3 membrane element manufacturer in China.

Yes , you can have Jiangsu Longmem Technology Co., Ltd. sample for starting the business , but it is not free.

Please contact Logmem team for detail .

content is empty!

Email Address

Phone Number

Address