LM-3213-800G-FL1

Longmem

11.7"x0.78"x0.66"x1.77“

0.23kg

Carton, OEM/ODM

7-14 days

ISO9001,ISO50001,GJB9001C,EAC,HALA,NSF

Accept

Drinking Water,Purifier and etc.

| Availability: | |

|---|---|

Longmem Residential Membrane ranks the best brands in China among RO membrane industry. It has won the support of thousands of families for feeding the reliable purified water since foundation. Each membrane is made of developed & pre-examined sheet and goes through stringent making processes as well as in-house quality inspection & testing before delivery.

RO membrane (reverse osmosis membrane): The membrane has a pore size of 0.0001 microns, which removes more than 99% of all impurities in the water except water molecules to get pure water, which solves the treatment of highly polluted water and high hardness water.

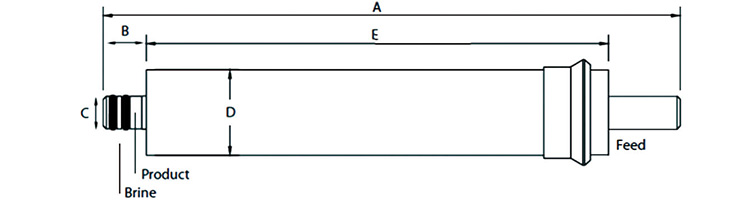

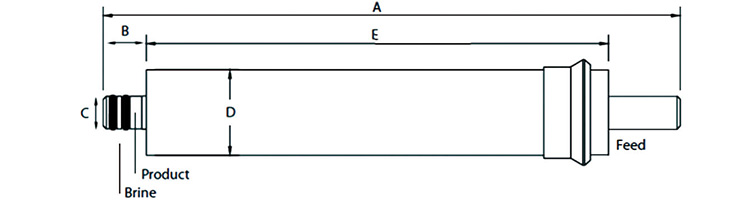

| Model No. | A (inch/mm) | B (inch/mm) | C (inch/mm) | D (inch/mm) | E (inch/mm) |

| LM-1812-50 | 11.7/298 | 0.78/20 | 0.66/16.8 | 1.73/44 | 10.2/258 |

| LM-1812-75 | 11.7/298 | 0.78/20 | 0.66/16.8 | 1.77/45 | 10.2/258 |

| LM-2012-100 | 11.7/298 | 0.78/20 | 0.66/16.8 | 1.85/47 | 10.4/258 |

| LM-2012-125 | 11.7/298 | 0.78/20 | 0.66/16.8 | 1.85/47 | 10.4/258 |

| LM-2012-150 | 11.7/298 | 0.78/20 | 0.66/16.8 | 1.9/48.5 | 10.4/258 |

| LM-2012-200 | 11.7/298 | 0.78/20 | 0.66/16.8 | 1.9/48 | 10.4/258 |

Note:The produced water amount listed in the table is an average value, compared with the standard value, the difference of the minimum amount of water produced by a single membrane does not exceed ± 15%.

| Model | TFC-1810-50 | TFC-1810-75 | TFC-1810-100 | TFC-2012-125 | TFC-2012-150 | TFC-2012- 200 | |

| TFC-1812-50 | TFC-1812-75 | TFC-2012-100 | |||||

| Perfor-mance | Stable Desalination % | 97 | 97 | 97 | 97 | 97 | 97 |

| Min. Desalination % | 96 | 96 | 96 | 96 | 96 | 96 | |

| Mean Permeable Flow GPD (L/d) | 50 (204) | 75 (281) | 100 (380) | 125 (478) | 150 (567.75) | 200(760) | |

| Active Film Area ft2(m2) | 3.5 (0.32) | 4.2 (0.38) | 5.0 (0.46) | 5.0 (0.50) | 6.0 (0.8) | 10.33 (0.96) | |

| Test Conditions | Pressure | 65psi (0.45Mpa) | |||||

| Water Temp. | 25℃ | ||||||

| Concentration(NaCl) | 500ppm | ||||||

| Water PH | 6.5 to 7.5 | ||||||

| Recovery Rate % | 15 | ||||||

| Operating Conditions | Max. Operating Pressure | 200psi (2.0Mpa) | |||||

| Max. Feed Water Temp. | 45℃ | ||||||

| Max. Feed Water Silt Density Index (SDI) | 5 | ||||||

| Feed Water Chlorine Tolerance | < 0.1 mg/l | ||||||

| Feed Water PH Range, Continuous Operation | 3 to 10 | ||||||

| Feed Water PH Range, Short-Term Cleaning | 2 to 11 | ||||||

| Max. Pressure Drop of Single Membrane | 10psi (0.07Mpa) | ||||||

| Model No. | Maximum Operating Temperature | Maximum Operating Pressure | Feed Water PH Range, continuous operation | Maximum Feed Water Turbidity | Maximum Feed Water SDI | Chlorine Tolerance |

| TFC-1812-50 | 45℃ | 200psi | 4-11 | 1NTU | 5 | <0.1ppm |

| TFC-1812-75 | 45℃ | 200psi | 4-11 | 1NTU | 5 | <0.1ppm |

| TFC-2012-100 | 45℃ | 200psi | 4-11 | 1NTU | 5 | <0.1ppm |

| TFC-2012-125 | 45℃ | 200psi | 4-11 | 1NTU | 5 | <0.1ppm |

| TFC-2012-150 | 45℃ | 200psi | 4-11 | 1NTU | 5 | <0.1ppm |

| TFC-2012-200 | 45℃ | 200psi | 4-11 | 1NTU | 5 | <0.1ppm |

RO Membrane Film

RO Membrane Element

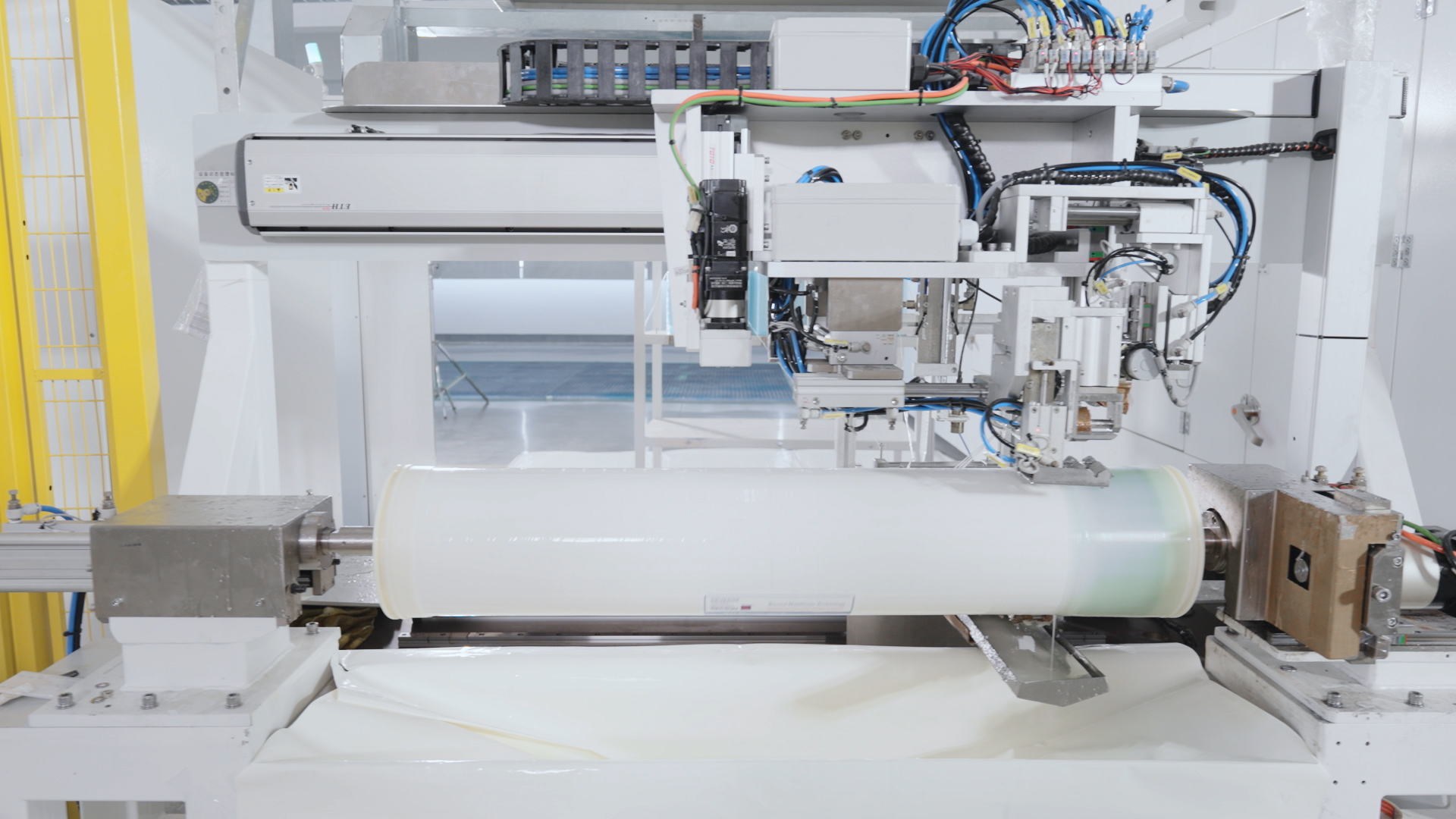

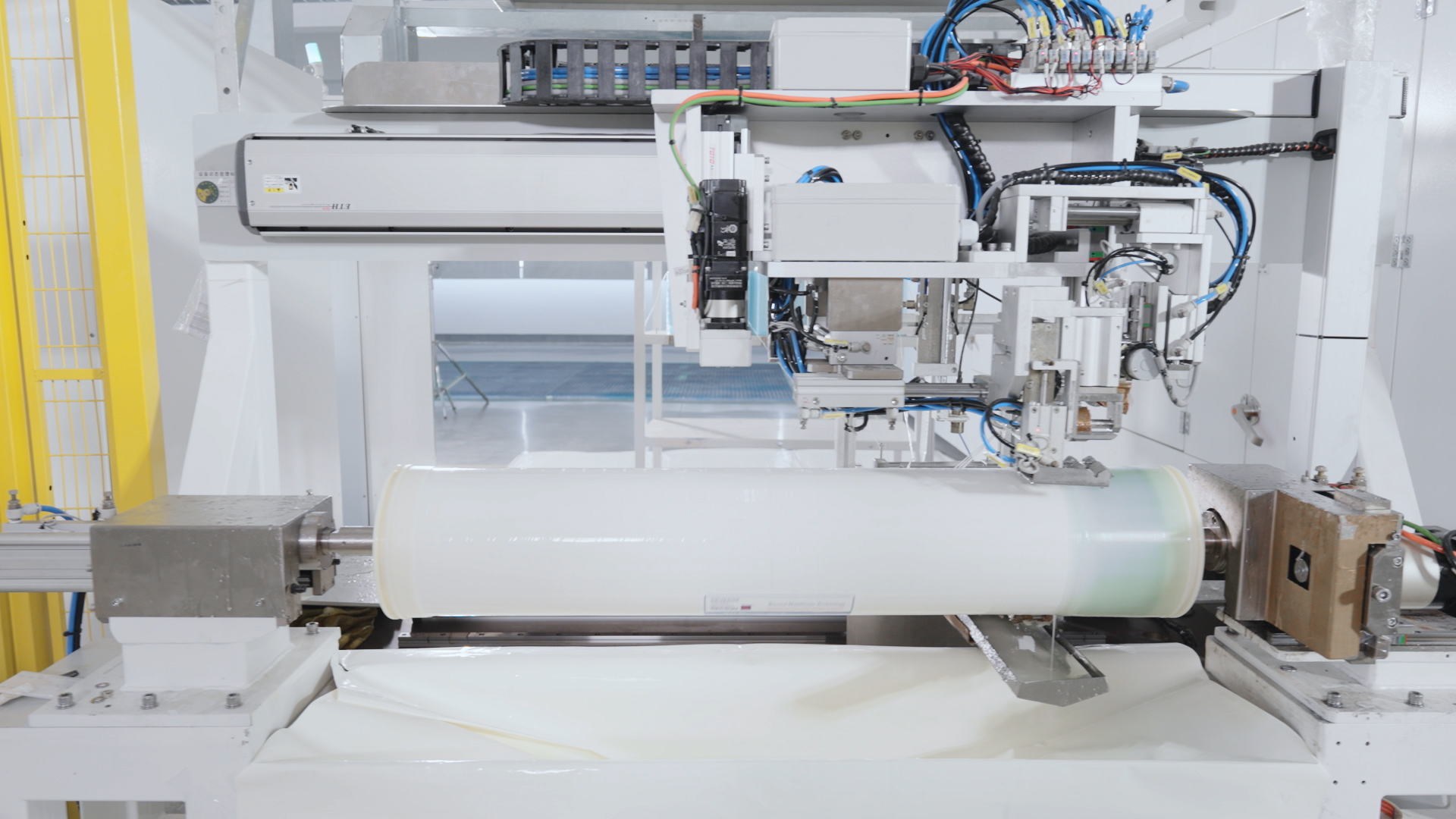

The production of reverse osmosis (RO) membrane elements involves several steps:

The first step is to create a thin, flat sheet of the RO membrane material. This is done by spreading a liquid polymer solution onto a casting surface, such as a glass plate or a rotating drum. The solution is then allowed to dry, forming a solid thin film.

After the casting process, the thin film is treated with chlorine gas or another oxidizing agent to improve its chemical resistance and remove any impurities.

The chlorine-treated thin film is then sintered by heating it at high temperatures. This step helps to further enhance the membrane's chemical stability and mechanical strength.

A mesh-like spacer material is applied on top of one side of the sintered membrane sheet. This spacer creates channels for water flow through the element and helps maintain separation between layers during assembly.

Multiple layers of spacer-applied membranes are rolled together into a tightly wound spiral configuration, with each layer separated by feed spacers that ensure proper water flow distribution throughout the element.

The ends of the spiral-wound element are capped off with end caps made from various materials like plastics or metals (e.g., epoxy resin). These caps provide structural support and prevent leakage at the ends of the element.

Each RO membrane element undergoes rigorous testing to ensure its performance meets industry standards before it can be approved for commercial use.

It's important to note that this process may vary slightly depending on specific manufacturing techniques used by different companies or variations in product designs.

There are several advantages of using a domestic reverse osmosis membrane element for water filtration:

Reverse osmosis membranes have a high rejection rate for a wide range of contaminants, including bacteria, viruses, heavy metals, pesticides, chemicals, and other impurities. This ensures that the treated water is clean and safe to drink.

Reverse osmosis removes chlorine and other compounds that can give tap water an unpleasant taste or odor. This results in better-tasting drinking water and enhances the overall sensory.

Domestic reverse osmosis systems are usually designed to be compact and space-efficient. They can easily fit under the kitchen sink or in other small spaces without taking up too much room.

While the initial investment in a domestic reverse osmosis system may be higher compared to other types of filtration systems, it can save money in the long run by reducing the need for bottled water purchases or expensive filter replacements.

Having a domestic reverse osmosis system at home eliminates the need to purchase bottled

Domestic or residential reverse osmosis membrane elements can be applied in various settings, including:

Reverse osmosis systems are commonly used in households to ensure the provision of clean and safe drinking water for the entire family.

These membrane elements can also be installed in multi-family units to provide filtered water to multiple households within a single building.

Many offices choose to install reverse osmosis systems to provide employees with access to clean and refreshing drinking water throughout the workday.

Reverse osmosis systems are often utilized in food service establishments to ensure that the water used for cooking, brewing coffee, or making drinks is free from impurities that could affect taste or quality.

Providing students with access to clean drinking water is essential for their health and well-being. Reverse osmosis systems can be installed in schools and other educational institutions for this purpose.

Hospitals, clinics, dental offices, and other healthcare facilities require reliable sources of purified water for various medical procedures, laboratory testing, dialysis machines,and other applications. Reverse osmosis membrane elements can be used to meet these requirements.

Offering clean and safe drinking water to guests is a top priority for hotels and resorts. Reverse osmosis systems can be installed in these establishments to ensure high-quality water for drinking, cooking, and other purposes.

Many gyms and fitness centers provide drinking water stations for their members. Reverse osmosis systems can be used in these facilities to offer purified water that is free from contaminants.

Reverse osmosis systems designed for portable use can be utilized in campsites or recreational vehicles (RVs) to provide clean drinking water during outdoor activities or while traveling.

Reverse osmosis systems can also be installed on boats or yachts to desal seawater, making it suitable for drinking, cooking, showering, and other onboard uses.

Overall, domestic/residential reverse osmosis membrane elements can be applied in any setting where there is a need for clean, purified water for drinking or various other purposes.

While the Domestic/Residential Reverse Osmosis Membrane Element

Reverse Osmosis Membrane Element is a highly efficient and reliable product, there are a few warnings and considerations to keep in mind:

It is crucial to install the membrane element correctly, following the manufacturer's guidelines and instructions. Improper installation can lead to reduced performance or damage to the membrane.

The quality of the feed water should be within the recommended limits specified by the manufacturer. High levels of suspended solids, organic matter, chlorine, or other contaminants can potentially damage or foul the membrane.

Brackish water contains various minerals and salts that can accumulate on the surface of the membrane over time, leading to fouling or scaling issues. Regular maintenance and cleaning procedures should be implemented to prevent these problems.

It is important to ensure that the membrane element is compatible with the chemicals used in the feed water or cleaning solutions. Some chemicals may degrade or damage the membrane, leading to reduced performance or premature failure.

The membrane element should be operated within the recommended pressure and temperature limits specified by the manufacturer. Operating outside of these limits can negatively impact performance and longevity.

Proper maintenance is essential for optimal performance and longevity of the membrane element. This includes routine cleaning, monitoring of operating parameters, and replacement of worn-out parts as necessary.

If you are unsure about any aspect of installing, operating, or maintaining the Reverse Osmosis Membrane Element, it is recommended to seek professional assistance from a qualified technician or water treatment specialist.

By following these warnings and guidelines, you can maximize the lifespan and efficiency of your brackish water reverse osmosis membrane elements.

There are several reasons why you choose to cooperate with Jiangsu Longmem Technology Co., Ltd.:

Jiangsu Longmem Technology Co., Ltd. has a wealth of experience in the industry specialied in water treatment technologies and solutions. They have a team of experts who possess extensive knowledge and expertise in their field.

The company is known for its advanced technological solutions for water treatment, including membrane filtration systems, reverse osmosis, and other cutting-edge technologies. By cooperating with them, one can benefit from state-of-the-art equipment and solutions.

Jiangsu Longmem Technology Co., Ltd. offers customized solutions tailored to the specific needs of their clients. They take into account various factors such as water quality, quantity, and budget constraints to provide effective and efficient solutions.

The company is committed to providing high-quality products and services to its customers. They adhere to strict quality control measures throughout the production process, ensuring that their products meet international standards.

Jiangsu Longmem Technology Co., Ltd.'s customer support team is dedicated to providing prompt assistance and after-sales services to their clients around the world. This ensures that any issues or concerns are addressed promptly.

The company has built a strong reputation in the industry for delivering reliable water treatment solutions over many years of operation.

Overall, by choosing to cooperate with Jiangsu Longmem Technology Co., Ltd., one can access their expertise, advanced technologies, customized solutions, high-quality products/services along with excellent customer support—all factors contributing towards successful collaboration in achieving efficient water treatment goals.

Longmem in Exhibition

Longmem in Exhibition

Jiangsu Longmem Technology Co., Ltd., is top 3 RO membrane manufacturer in China.

Yes , you can have Jiangsu Longmem Technology Co., Ltd. sample for starting the business.

Please contact Logmem team for detail .

Longmem Residential Membrane ranks the best brands in China among RO membrane industry. It has won the support of thousands of families for feeding the reliable purified water since foundation. Each membrane is made of developed & pre-examined sheet and goes through stringent making processes as well as in-house quality inspection & testing before delivery.

RO membrane (reverse osmosis membrane): The membrane has a pore size of 0.0001 microns, which removes more than 99% of all impurities in the water except water molecules to get pure water, which solves the treatment of highly polluted water and high hardness water.

| Model No. | A (inch/mm) | B (inch/mm) | C (inch/mm) | D (inch/mm) | E (inch/mm) |

| LM-1812-50 | 11.7/298 | 0.78/20 | 0.66/16.8 | 1.73/44 | 10.2/258 |

| LM-1812-75 | 11.7/298 | 0.78/20 | 0.66/16.8 | 1.77/45 | 10.2/258 |

| LM-2012-100 | 11.7/298 | 0.78/20 | 0.66/16.8 | 1.85/47 | 10.4/258 |

| LM-2012-125 | 11.7/298 | 0.78/20 | 0.66/16.8 | 1.85/47 | 10.4/258 |

| LM-2012-150 | 11.7/298 | 0.78/20 | 0.66/16.8 | 1.9/48.5 | 10.4/258 |

| LM-2012-200 | 11.7/298 | 0.78/20 | 0.66/16.8 | 1.9/48 | 10.4/258 |

Note:The produced water amount listed in the table is an average value, compared with the standard value, the difference of the minimum amount of water produced by a single membrane does not exceed ± 15%.

| Model | TFC-1810-50 | TFC-1810-75 | TFC-1810-100 | TFC-2012-125 | TFC-2012-150 | TFC-2012- 200 | |

| TFC-1812-50 | TFC-1812-75 | TFC-2012-100 | |||||

| Perfor-mance | Stable Desalination % | 97 | 97 | 97 | 97 | 97 | 97 |

| Min. Desalination % | 96 | 96 | 96 | 96 | 96 | 96 | |

| Mean Permeable Flow GPD (L/d) | 50 (204) | 75 (281) | 100 (380) | 125 (478) | 150 (567.75) | 200(760) | |

| Active Film Area ft2(m2) | 3.5 (0.32) | 4.2 (0.38) | 5.0 (0.46) | 5.0 (0.50) | 6.0 (0.8) | 10.33 (0.96) | |

| Test Conditions | Pressure | 65psi (0.45Mpa) | |||||

| Water Temp. | 25℃ | ||||||

| Concentration(NaCl) | 500ppm | ||||||

| Water PH | 6.5 to 7.5 | ||||||

| Recovery Rate % | 15 | ||||||

| Operating Conditions | Max. Operating Pressure | 200psi (2.0Mpa) | |||||

| Max. Feed Water Temp. | 45℃ | ||||||

| Max. Feed Water Silt Density Index (SDI) | 5 | ||||||

| Feed Water Chlorine Tolerance | < 0.1 mg/l | ||||||

| Feed Water PH Range, Continuous Operation | 3 to 10 | ||||||

| Feed Water PH Range, Short-Term Cleaning | 2 to 11 | ||||||

| Max. Pressure Drop of Single Membrane | 10psi (0.07Mpa) | ||||||

| Model No. | Maximum Operating Temperature | Maximum Operating Pressure | Feed Water PH Range, continuous operation | Maximum Feed Water Turbidity | Maximum Feed Water SDI | Chlorine Tolerance |

| TFC-1812-50 | 45℃ | 200psi | 4-11 | 1NTU | 5 | <0.1ppm |

| TFC-1812-75 | 45℃ | 200psi | 4-11 | 1NTU | 5 | <0.1ppm |

| TFC-2012-100 | 45℃ | 200psi | 4-11 | 1NTU | 5 | <0.1ppm |

| TFC-2012-125 | 45℃ | 200psi | 4-11 | 1NTU | 5 | <0.1ppm |

| TFC-2012-150 | 45℃ | 200psi | 4-11 | 1NTU | 5 | <0.1ppm |

| TFC-2012-200 | 45℃ | 200psi | 4-11 | 1NTU | 5 | <0.1ppm |

RO Membrane Film

RO Membrane Element

The production of reverse osmosis (RO) membrane elements involves several steps:

The first step is to create a thin, flat sheet of the RO membrane material. This is done by spreading a liquid polymer solution onto a casting surface, such as a glass plate or a rotating drum. The solution is then allowed to dry, forming a solid thin film.

After the casting process, the thin film is treated with chlorine gas or another oxidizing agent to improve its chemical resistance and remove any impurities.

The chlorine-treated thin film is then sintered by heating it at high temperatures. This step helps to further enhance the membrane's chemical stability and mechanical strength.

A mesh-like spacer material is applied on top of one side of the sintered membrane sheet. This spacer creates channels for water flow through the element and helps maintain separation between layers during assembly.

Multiple layers of spacer-applied membranes are rolled together into a tightly wound spiral configuration, with each layer separated by feed spacers that ensure proper water flow distribution throughout the element.

The ends of the spiral-wound element are capped off with end caps made from various materials like plastics or metals (e.g., epoxy resin). These caps provide structural support and prevent leakage at the ends of the element.

Each RO membrane element undergoes rigorous testing to ensure its performance meets industry standards before it can be approved for commercial use.

It's important to note that this process may vary slightly depending on specific manufacturing techniques used by different companies or variations in product designs.

There are several advantages of using a domestic reverse osmosis membrane element for water filtration:

Reverse osmosis membranes have a high rejection rate for a wide range of contaminants, including bacteria, viruses, heavy metals, pesticides, chemicals, and other impurities. This ensures that the treated water is clean and safe to drink.

Reverse osmosis removes chlorine and other compounds that can give tap water an unpleasant taste or odor. This results in better-tasting drinking water and enhances the overall sensory.

Domestic reverse osmosis systems are usually designed to be compact and space-efficient. They can easily fit under the kitchen sink or in other small spaces without taking up too much room.

While the initial investment in a domestic reverse osmosis system may be higher compared to other types of filtration systems, it can save money in the long run by reducing the need for bottled water purchases or expensive filter replacements.

Having a domestic reverse osmosis system at home eliminates the need to purchase bottled

Domestic or residential reverse osmosis membrane elements can be applied in various settings, including:

Reverse osmosis systems are commonly used in households to ensure the provision of clean and safe drinking water for the entire family.

These membrane elements can also be installed in multi-family units to provide filtered water to multiple households within a single building.

Many offices choose to install reverse osmosis systems to provide employees with access to clean and refreshing drinking water throughout the workday.

Reverse osmosis systems are often utilized in food service establishments to ensure that the water used for cooking, brewing coffee, or making drinks is free from impurities that could affect taste or quality.

Providing students with access to clean drinking water is essential for their health and well-being. Reverse osmosis systems can be installed in schools and other educational institutions for this purpose.

Hospitals, clinics, dental offices, and other healthcare facilities require reliable sources of purified water for various medical procedures, laboratory testing, dialysis machines,and other applications. Reverse osmosis membrane elements can be used to meet these requirements.

Offering clean and safe drinking water to guests is a top priority for hotels and resorts. Reverse osmosis systems can be installed in these establishments to ensure high-quality water for drinking, cooking, and other purposes.

Many gyms and fitness centers provide drinking water stations for their members. Reverse osmosis systems can be used in these facilities to offer purified water that is free from contaminants.

Reverse osmosis systems designed for portable use can be utilized in campsites or recreational vehicles (RVs) to provide clean drinking water during outdoor activities or while traveling.

Reverse osmosis systems can also be installed on boats or yachts to desal seawater, making it suitable for drinking, cooking, showering, and other onboard uses.

Overall, domestic/residential reverse osmosis membrane elements can be applied in any setting where there is a need for clean, purified water for drinking or various other purposes.

While the Domestic/Residential Reverse Osmosis Membrane Element

Reverse Osmosis Membrane Element is a highly efficient and reliable product, there are a few warnings and considerations to keep in mind:

It is crucial to install the membrane element correctly, following the manufacturer's guidelines and instructions. Improper installation can lead to reduced performance or damage to the membrane.

The quality of the feed water should be within the recommended limits specified by the manufacturer. High levels of suspended solids, organic matter, chlorine, or other contaminants can potentially damage or foul the membrane.

Brackish water contains various minerals and salts that can accumulate on the surface of the membrane over time, leading to fouling or scaling issues. Regular maintenance and cleaning procedures should be implemented to prevent these problems.

It is important to ensure that the membrane element is compatible with the chemicals used in the feed water or cleaning solutions. Some chemicals may degrade or damage the membrane, leading to reduced performance or premature failure.

The membrane element should be operated within the recommended pressure and temperature limits specified by the manufacturer. Operating outside of these limits can negatively impact performance and longevity.

Proper maintenance is essential for optimal performance and longevity of the membrane element. This includes routine cleaning, monitoring of operating parameters, and replacement of worn-out parts as necessary.

If you are unsure about any aspect of installing, operating, or maintaining the Reverse Osmosis Membrane Element, it is recommended to seek professional assistance from a qualified technician or water treatment specialist.

By following these warnings and guidelines, you can maximize the lifespan and efficiency of your brackish water reverse osmosis membrane elements.

There are several reasons why you choose to cooperate with Jiangsu Longmem Technology Co., Ltd.:

Jiangsu Longmem Technology Co., Ltd. has a wealth of experience in the industry specialied in water treatment technologies and solutions. They have a team of experts who possess extensive knowledge and expertise in their field.

The company is known for its advanced technological solutions for water treatment, including membrane filtration systems, reverse osmosis, and other cutting-edge technologies. By cooperating with them, one can benefit from state-of-the-art equipment and solutions.

Jiangsu Longmem Technology Co., Ltd. offers customized solutions tailored to the specific needs of their clients. They take into account various factors such as water quality, quantity, and budget constraints to provide effective and efficient solutions.

The company is committed to providing high-quality products and services to its customers. They adhere to strict quality control measures throughout the production process, ensuring that their products meet international standards.

Jiangsu Longmem Technology Co., Ltd.'s customer support team is dedicated to providing prompt assistance and after-sales services to their clients around the world. This ensures that any issues or concerns are addressed promptly.

The company has built a strong reputation in the industry for delivering reliable water treatment solutions over many years of operation.

Overall, by choosing to cooperate with Jiangsu Longmem Technology Co., Ltd., one can access their expertise, advanced technologies, customized solutions, high-quality products/services along with excellent customer support—all factors contributing towards successful collaboration in achieving efficient water treatment goals.

Longmem in Exhibition

Longmem in Exhibition

Jiangsu Longmem Technology Co., Ltd., is top 3 RO membrane manufacturer in China.

Yes , you can have Jiangsu Longmem Technology Co., Ltd. sample for starting the business.

Please contact Logmem team for detail .

content is empty!

Email Address

Phone Number

Address