LM4040-ULP-FL1

Longmem

40"x3.9"x0.75"x1.05"

3.5kg

Carton, OEM/ODM

7-14 days

ISO9001,ISO50001,GJB9001C,EAC,HALA,NSF

Accept

Municipal and Residential Drinking Water,Irrigation and etc.

| Availability: | |

|---|---|

The LM4040-ULP-FL1 is an ultra-low pressure reverse osmosis (RO) membrane element designed to provide highly efficient water purification while minimizing energy consumption. This membrane element is part of the LM4040 series, which is known for its exceptional performance and cost-effectiveness.

The LM4040-ULP-FL1 combines advanced thin-film composite (TFC) technology with a unique spiral-wound design to deliver outstanding water permeability and rejection rates. It features a thin polyamide layer that effectively removes dissolved salts, bacteria, viruses, and other contaminants from water sources.

What sets the LM4040-ULP-FL1 apart is its ability to operate at extremely low pressures. This allows it to significantly reduce energy requirements compared to conventional RO membranes without sacrificing performance or compromising water quality.

This membrane element is ideal for various applications where energy efficiency is crucial, such as desalination plants, industrial wastewater treatment systems, potable water production facilities, and other large-scale water purification processes. With its high productivity and low operating costs, the LM4040-ULP-FL1 offers an environmentally-friendly solution that helps conserve resources while ensuring clean and safe drinking water.

In summary, the LM4040-ULP FL1 is an altra-low pressure reverse osmosis membrane element that combines advanced TFC technology and a unique design to provide highly efficient water purification with minimal energy consumption. Its ability to operate at extremely low pressures makes it suitable for various applications where energy efficiency is a priority.

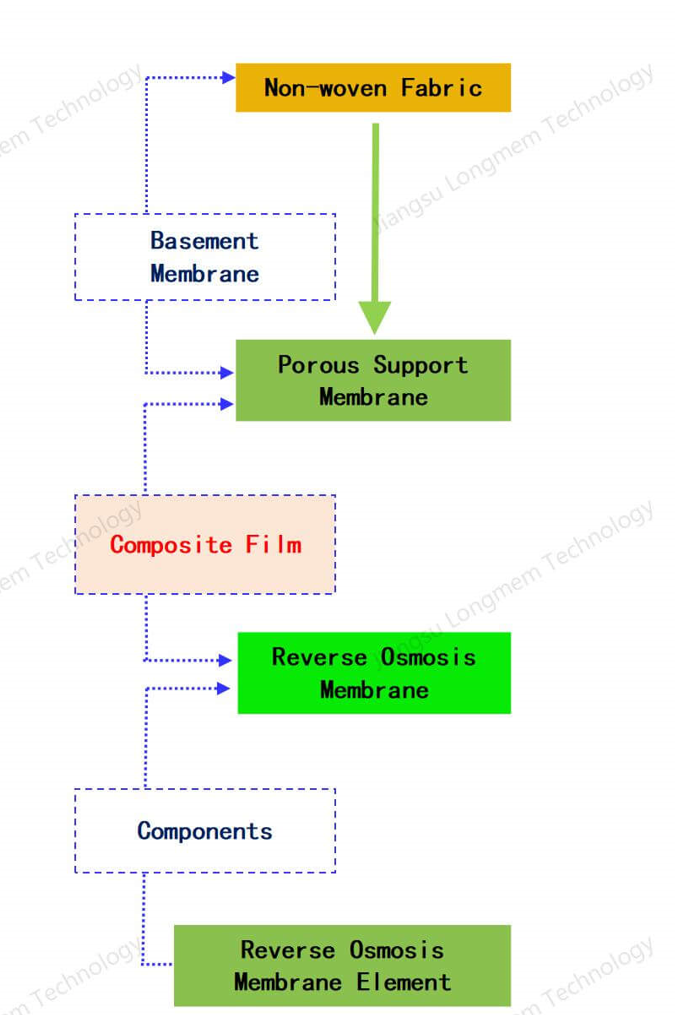

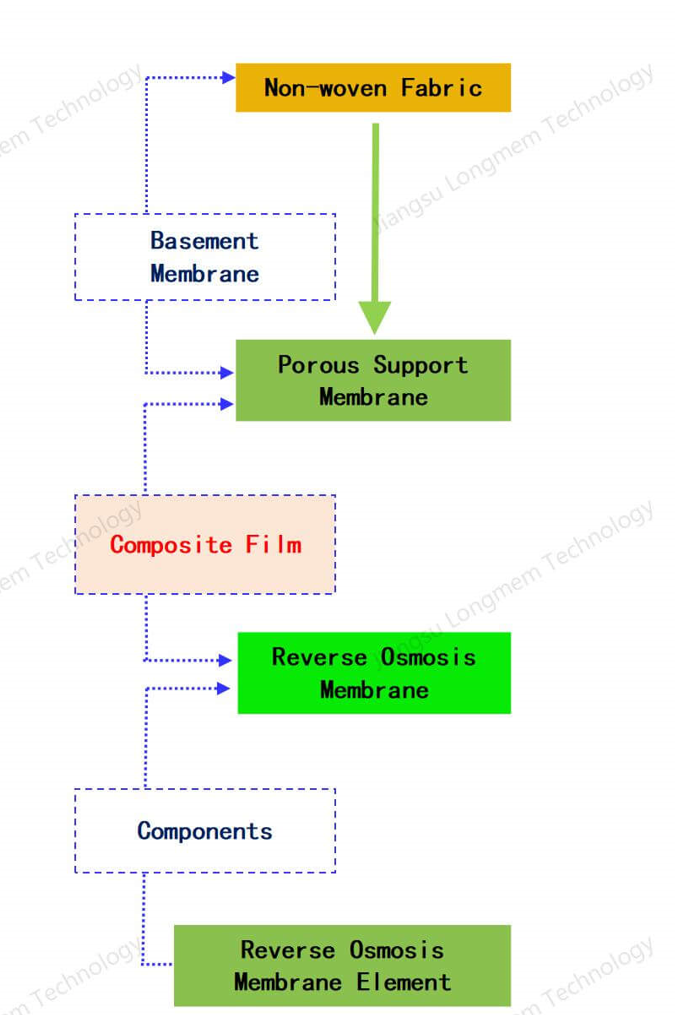

RO Membrane Film

RO Membrane Element

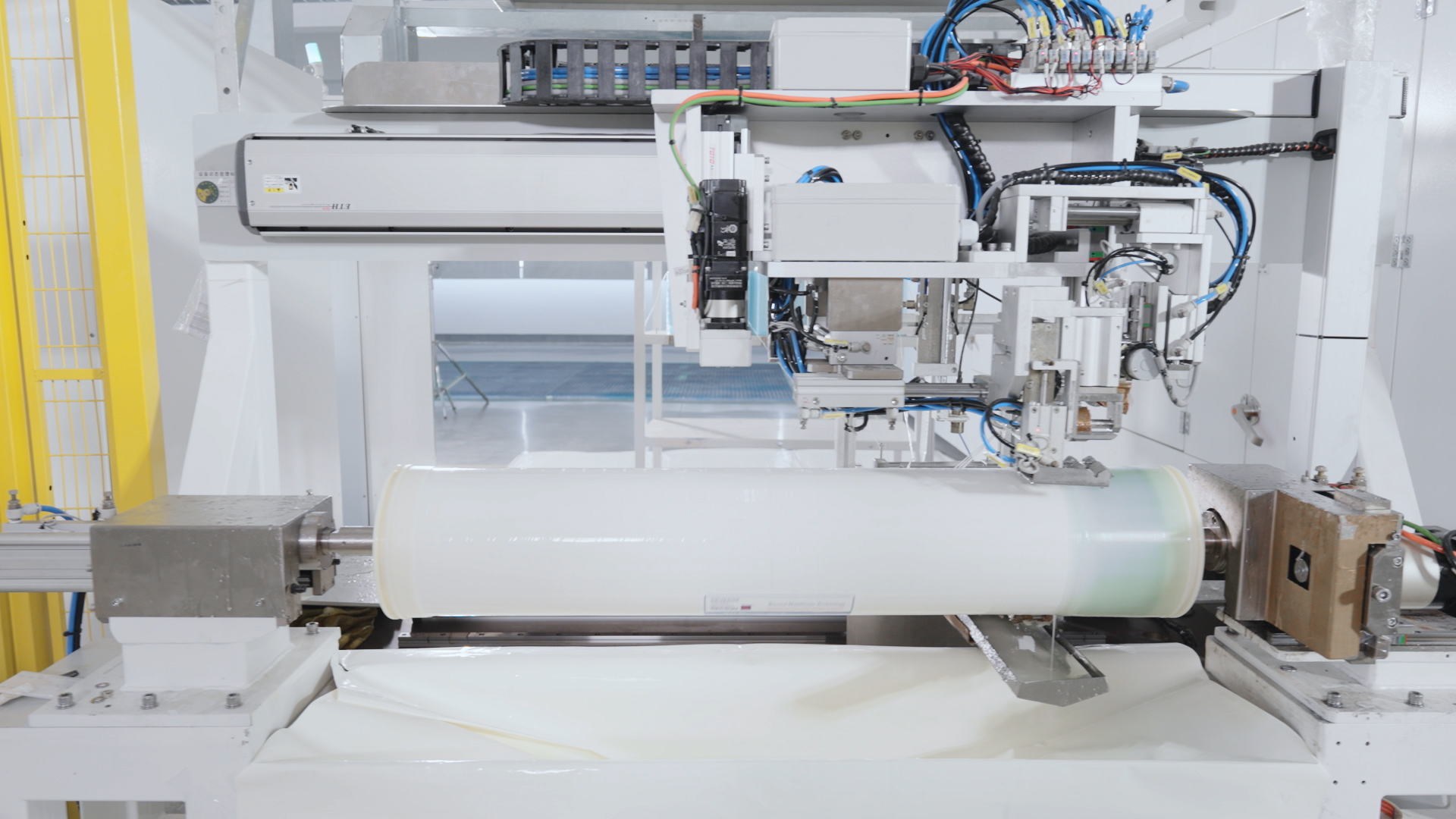

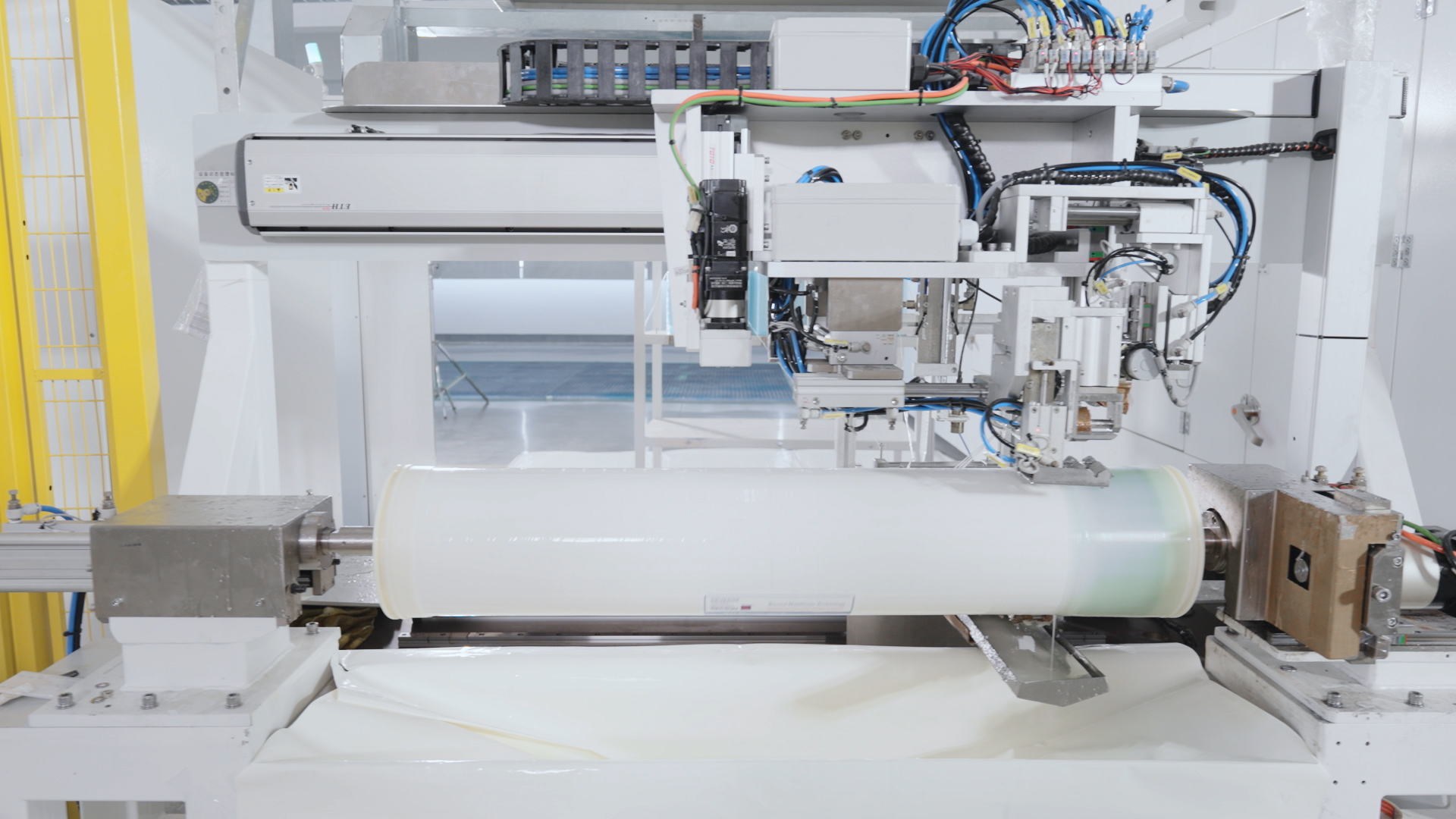

The Ultra-Low Pressure Reverse Osmosis Membrane Element, specifically the LM4040-ULP-FL1, is a product that is manufactured by Longmem Technology Co., Ltd. There are several general steps involved:

The membrane element supplier conducts research and development activities to design a reverse osmosis (RO) membrane specifically suitable for treating brackish water while being resistant to fouling.

The supplier selects high-quality materials that can withstand brackish water conditions and prevent fouling.

The selected materials are combined and cast in a flat sheet form using specialized casting techniques. This sheet is then cut into desired sizes to create individual membranes.

The individual membranes undergo further treatment processes such as coating or grafting with anti-fouling agents or surface modifications to enhance their resistance against fouling.

The membranes are rolled into membrane elements by placing them between permeate spacers and feed spacers, which provide structural support and create channels for water flow during operation.

Each finished LM4040-ULP-FL1 membrane element undergoes rigorous testing.

LM4040-ULP-FL1-Ultra Low Pressure Specification.pdf

LM4040-ULP-FL1-Ultra Low Pressure Specification.pdf

Test conditions: 500ppm (NaCl) water, 25°C (77°F); 100psi (0.69MPa);

15% recovery

Permeate flows variation: +/-15%

Always keep new elements in the original packaging

Avoid exposure to direct sunlight

Avoid exposure to chlorine and oxidizing agents

3-year warranty

Oxidation damage is not covered under warranty

Keep elements moist at all times after initial wetting

The initial permeate (first hour) must be discarded

During prolonged system shutdowns, membrane elements must be immersed in preservative solution.

The solution must be rinsed out before operation starts again

The LM4040-ULP-FL1 ultra-low pressure reverse osmosis (RO) membrane element offers several advantages:

Despite operating at lower pressures, ULP RO membranes maintain high salt rejection rates. This ensures effective removal of dissolved salts from the feedwater, resulting in high-quality purified water.

ULP RO membrane elements are typically smaller in size compared to traditional RO membranes with similar production capacities. This allows for easier installation and flexibility in system design.

ULP RO membrane elements undergo rigorous testing and quality control measures to ensure consistent performance over time. This reliability gives users peace of mind knowing that their water purification needs will be consistently met.

Overall, the advantages of ULP RO membrane elements make them a cost-effective and efficient solution for various water treatment applications while minimizing environmental impact.

Ultra low-pressure RO membranes are commonly used for treating municipal water supplies, removing contaminants such as bacteria, viruses, dissolved salts, and organic compounds to produce safe drinking water.

These membrane elements can effectively treat industrial wastewater by removing pollutants and contaminants before discharge or reuse in the manufacturing process.

3. Food and beverage industry:

Ultra low-pressure RO membranes are utilized for purifying water used in the production of food and beverages, ensuring that the final products meet quality standards.

In pharmaceutical manufacturing processes where high-quality purified water is required for injections or other applications, ultra low-pressure RO membranes can provide the necessary purity levels.

5. Desalination plants:

These membrane elements play a crucial role in desalination plants by removing salt from seawater or brackish water to produce freshwater suitable for various purposes such as drinking or irrigation.

Ultra low-pressure RO membranes can be employed to purify brackish groundwater sources used for agricultural irrigation systems, preventing salt buildup that could harm crops.

In electronic component fabrication processes where ultrapure water is essential to prevent contamination or damage to delicate equipment, ultra low-pressure RO membranes help achieve the required purity levels.

8. Power generation industry:

Some power plants use reverse osmosis membrane technology to treat cooling tower blowdown water or wastewater generated during power generation processes before discharge or reuse.

Ultra-low pressure RO membrane elements are deployed for treating produced water during oil exploration operations before it is reused or safely discharged back into the environment.

10. Aquaculture farms:

These farms may implement ultra-low pressure RO technology to maintain optimum conditions by ensuring clean freshwater supply without harmful substances that could negatively impact fish health and growth.

It should be noted that specific design considerations may vary depending on each application's unique requirements and operating conditions

While the LM4040-ULP-FL1 Ultra Low Pressure Reverse Osmosis Membrane Element is a highly efficient and reliable product, there are a few warnings and considerations to keep in mind:

It is crucial to install the membrane element correctly, following the manufacturer's guidelines and instructions. Improper installation can lead to reduced performance or damage to the membrane.

The quality of the feed water should be within the recommended limits specified by the manufacturer. High levels of suspended solids, organic matter, chlorine, or other contaminants can potentially damage or foul the membrane.

Brackish water contains various minerals and salts that can accumulate on the surface of the membrane over time, leading to fouling or scaling issues. Regular maintenance and cleaning procedures should be implemented to prevent these problems.

It is important to ensure that the membrane element is compatible with the chemicals used in the feed water or cleaning solutions. Some chemicals may degrade or damage the membrane, leading to reduced performance or premature failure.

The membrane element should be operated within the recommended pressure and temperature limits specified by the manufacturer. Operating outside of these limits can negatively impact performance and longevity.

Proper maintenance is essential for optimal performance and longevity of the membrane element. This includes routine cleaning, monitoring of operating parameters, and replacement of worn-out parts as necessary.

If you are unsure about any aspect of installing, operating, or maintaining the LM4040 Reverse Osmosis Membrane Element, it is recommended to seek professional assistance from a qualified technician or water treatment specialist.

By following these warnings and guidelines, you can maximize the lifespan and efficiency of your brackish water reverse osmosis membrane elements.

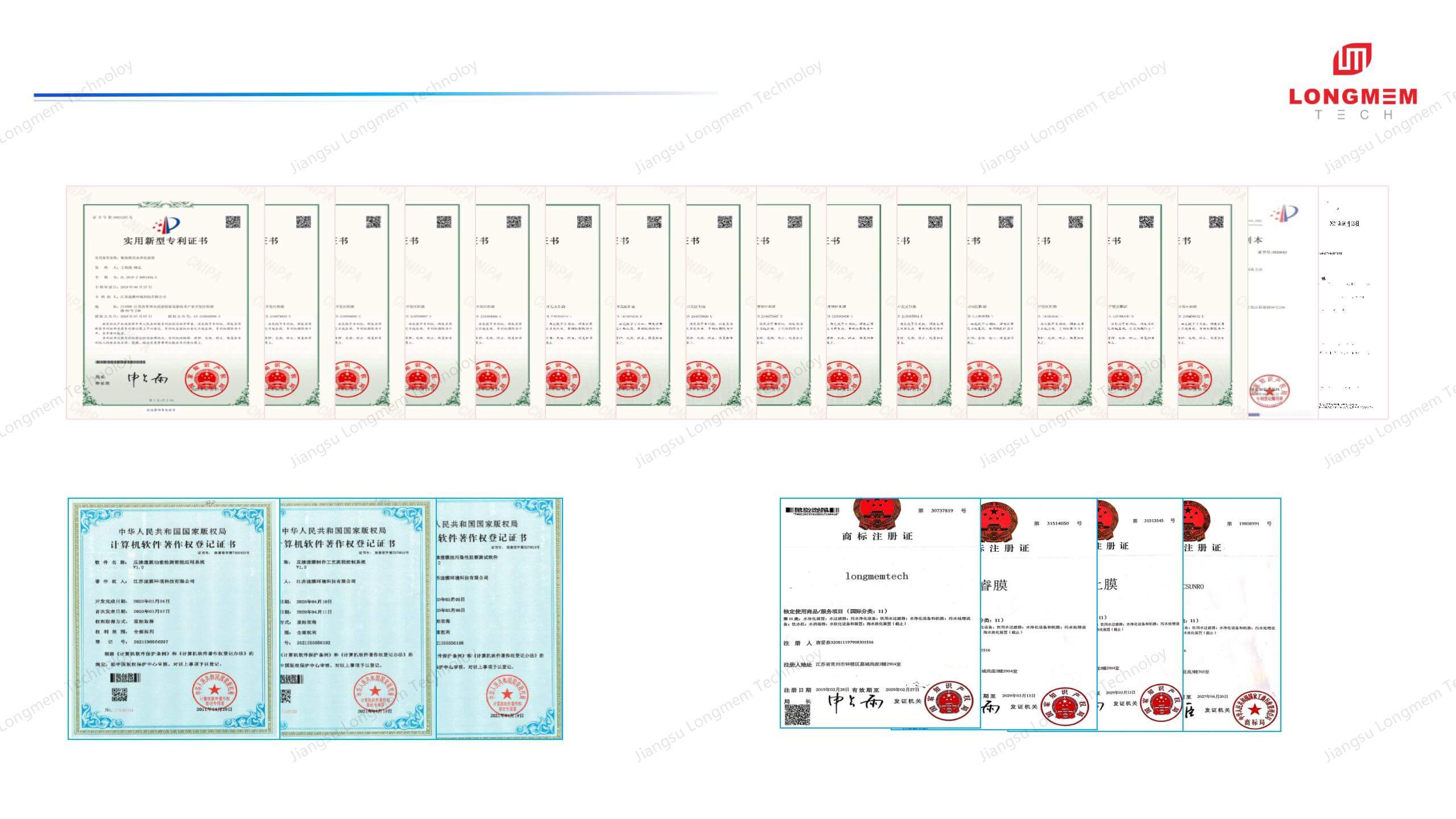

There are several reasons why you choose to cooperate with Jiangsu Longmem Technology Co., Ltd.:

Jiangsu Longmem Technology Co., Ltd. has a wealth of experience in the industry specialied in water treatment technologies and solutions. They have a team of experts who possess extensive knowledge and expertise in their field.

Jiangsu Longmem Technology Co., Ltd. is known for its advanced technological solutions for water treatment, including membrane filtration systems, reverse osmosis, and other cutting-edge technologies. By cooperating with them, one can benefit from state-of-the-art equipment and solutions.

Jiangsu Longmem Technology Co., Ltd. offers customized solutions tailored to the specific needs of their clients. They take into account various factors such as water quality, quantity, and budget constraints to provide effective and efficient solutions.

Jiangsu Longmem Technology Co., Ltd. is committed to providing high-quality products and services to its customers. They adhere to strict quality control measures throughout the production process, ensuring that their products meet international standards.

Jiangsu Longmem Technology Co., Ltd.'s customer support team is dedicated to providing prompt assistance and after-sales services to their clients around the world. This ensures that any issues or concerns are addressed promptly.

Jiangsu Longmem Technology Co., Ltd. has built a strong reputation in the industry for delivering reliable water treatment solutions over many years of operation.

Overall, by choosing to cooperate with Jiangsu Longmem Technology Co., Ltd., one can access their expertise, advanced technologies, customized solutions, high-quality products/services along with excellent customer support—all factors contributing towards successful collaboration in achieving efficient water treatment goals.

Ultra low pressure RO Membrane elements are specially designed to run at 100 psi while producing the same product flow as standard elements.

Yes , you can have Jiangsu Longmem Technology Co., Ltd. sample for starting the business , but it is not free.

Please contact Logmem team for detail .

The LM4040-ULP-FL1 is an ultra-low pressure reverse osmosis (RO) membrane element designed to provide highly efficient water purification while minimizing energy consumption. This membrane element is part of the LM4040 series, which is known for its exceptional performance and cost-effectiveness.

The LM4040-ULP-FL1 combines advanced thin-film composite (TFC) technology with a unique spiral-wound design to deliver outstanding water permeability and rejection rates. It features a thin polyamide layer that effectively removes dissolved salts, bacteria, viruses, and other contaminants from water sources.

What sets the LM4040-ULP-FL1 apart is its ability to operate at extremely low pressures. This allows it to significantly reduce energy requirements compared to conventional RO membranes without sacrificing performance or compromising water quality.

This membrane element is ideal for various applications where energy efficiency is crucial, such as desalination plants, industrial wastewater treatment systems, potable water production facilities, and other large-scale water purification processes. With its high productivity and low operating costs, the LM4040-ULP-FL1 offers an environmentally-friendly solution that helps conserve resources while ensuring clean and safe drinking water.

In summary, the LM4040-ULP FL1 is an altra-low pressure reverse osmosis membrane element that combines advanced TFC technology and a unique design to provide highly efficient water purification with minimal energy consumption. Its ability to operate at extremely low pressures makes it suitable for various applications where energy efficiency is a priority.

RO Membrane Film

RO Membrane Element

The Ultra-Low Pressure Reverse Osmosis Membrane Element, specifically the LM4040-ULP-FL1, is a product that is manufactured by Longmem Technology Co., Ltd. There are several general steps involved:

The membrane element supplier conducts research and development activities to design a reverse osmosis (RO) membrane specifically suitable for treating brackish water while being resistant to fouling.

The supplier selects high-quality materials that can withstand brackish water conditions and prevent fouling.

The selected materials are combined and cast in a flat sheet form using specialized casting techniques. This sheet is then cut into desired sizes to create individual membranes.

The individual membranes undergo further treatment processes such as coating or grafting with anti-fouling agents or surface modifications to enhance their resistance against fouling.

The membranes are rolled into membrane elements by placing them between permeate spacers and feed spacers, which provide structural support and create channels for water flow during operation.

Each finished LM4040-ULP-FL1 membrane element undergoes rigorous testing.

LM4040-ULP-FL1-Ultra Low Pressure Specification.pdf

LM4040-ULP-FL1-Ultra Low Pressure Specification.pdf

Test conditions: 500ppm (NaCl) water, 25°C (77°F); 100psi (0.69MPa);

15% recovery

Permeate flows variation: +/-15%

Always keep new elements in the original packaging

Avoid exposure to direct sunlight

Avoid exposure to chlorine and oxidizing agents

3-year warranty

Oxidation damage is not covered under warranty

Keep elements moist at all times after initial wetting

The initial permeate (first hour) must be discarded

During prolonged system shutdowns, membrane elements must be immersed in preservative solution.

The solution must be rinsed out before operation starts again

The LM4040-ULP-FL1 ultra-low pressure reverse osmosis (RO) membrane element offers several advantages:

Despite operating at lower pressures, ULP RO membranes maintain high salt rejection rates. This ensures effective removal of dissolved salts from the feedwater, resulting in high-quality purified water.

ULP RO membrane elements are typically smaller in size compared to traditional RO membranes with similar production capacities. This allows for easier installation and flexibility in system design.

ULP RO membrane elements undergo rigorous testing and quality control measures to ensure consistent performance over time. This reliability gives users peace of mind knowing that their water purification needs will be consistently met.

Overall, the advantages of ULP RO membrane elements make them a cost-effective and efficient solution for various water treatment applications while minimizing environmental impact.

Ultra low-pressure RO membranes are commonly used for treating municipal water supplies, removing contaminants such as bacteria, viruses, dissolved salts, and organic compounds to produce safe drinking water.

These membrane elements can effectively treat industrial wastewater by removing pollutants and contaminants before discharge or reuse in the manufacturing process.

3. Food and beverage industry:

Ultra low-pressure RO membranes are utilized for purifying water used in the production of food and beverages, ensuring that the final products meet quality standards.

In pharmaceutical manufacturing processes where high-quality purified water is required for injections or other applications, ultra low-pressure RO membranes can provide the necessary purity levels.

5. Desalination plants:

These membrane elements play a crucial role in desalination plants by removing salt from seawater or brackish water to produce freshwater suitable for various purposes such as drinking or irrigation.

Ultra low-pressure RO membranes can be employed to purify brackish groundwater sources used for agricultural irrigation systems, preventing salt buildup that could harm crops.

In electronic component fabrication processes where ultrapure water is essential to prevent contamination or damage to delicate equipment, ultra low-pressure RO membranes help achieve the required purity levels.

8. Power generation industry:

Some power plants use reverse osmosis membrane technology to treat cooling tower blowdown water or wastewater generated during power generation processes before discharge or reuse.

Ultra-low pressure RO membrane elements are deployed for treating produced water during oil exploration operations before it is reused or safely discharged back into the environment.

10. Aquaculture farms:

These farms may implement ultra-low pressure RO technology to maintain optimum conditions by ensuring clean freshwater supply without harmful substances that could negatively impact fish health and growth.

It should be noted that specific design considerations may vary depending on each application's unique requirements and operating conditions

While the LM4040-ULP-FL1 Ultra Low Pressure Reverse Osmosis Membrane Element is a highly efficient and reliable product, there are a few warnings and considerations to keep in mind:

It is crucial to install the membrane element correctly, following the manufacturer's guidelines and instructions. Improper installation can lead to reduced performance or damage to the membrane.

The quality of the feed water should be within the recommended limits specified by the manufacturer. High levels of suspended solids, organic matter, chlorine, or other contaminants can potentially damage or foul the membrane.

Brackish water contains various minerals and salts that can accumulate on the surface of the membrane over time, leading to fouling or scaling issues. Regular maintenance and cleaning procedures should be implemented to prevent these problems.

It is important to ensure that the membrane element is compatible with the chemicals used in the feed water or cleaning solutions. Some chemicals may degrade or damage the membrane, leading to reduced performance or premature failure.

The membrane element should be operated within the recommended pressure and temperature limits specified by the manufacturer. Operating outside of these limits can negatively impact performance and longevity.

Proper maintenance is essential for optimal performance and longevity of the membrane element. This includes routine cleaning, monitoring of operating parameters, and replacement of worn-out parts as necessary.

If you are unsure about any aspect of installing, operating, or maintaining the LM4040 Reverse Osmosis Membrane Element, it is recommended to seek professional assistance from a qualified technician or water treatment specialist.

By following these warnings and guidelines, you can maximize the lifespan and efficiency of your brackish water reverse osmosis membrane elements.

There are several reasons why you choose to cooperate with Jiangsu Longmem Technology Co., Ltd.:

Jiangsu Longmem Technology Co., Ltd. has a wealth of experience in the industry specialied in water treatment technologies and solutions. They have a team of experts who possess extensive knowledge and expertise in their field.

Jiangsu Longmem Technology Co., Ltd. is known for its advanced technological solutions for water treatment, including membrane filtration systems, reverse osmosis, and other cutting-edge technologies. By cooperating with them, one can benefit from state-of-the-art equipment and solutions.

Jiangsu Longmem Technology Co., Ltd. offers customized solutions tailored to the specific needs of their clients. They take into account various factors such as water quality, quantity, and budget constraints to provide effective and efficient solutions.

Jiangsu Longmem Technology Co., Ltd. is committed to providing high-quality products and services to its customers. They adhere to strict quality control measures throughout the production process, ensuring that their products meet international standards.

Jiangsu Longmem Technology Co., Ltd.'s customer support team is dedicated to providing prompt assistance and after-sales services to their clients around the world. This ensures that any issues or concerns are addressed promptly.

Jiangsu Longmem Technology Co., Ltd. has built a strong reputation in the industry for delivering reliable water treatment solutions over many years of operation.

Overall, by choosing to cooperate with Jiangsu Longmem Technology Co., Ltd., one can access their expertise, advanced technologies, customized solutions, high-quality products/services along with excellent customer support—all factors contributing towards successful collaboration in achieving efficient water treatment goals.

Ultra low pressure RO Membrane elements are specially designed to run at 100 psi while producing the same product flow as standard elements.

Yes , you can have Jiangsu Longmem Technology Co., Ltd. sample for starting the business , but it is not free.

Please contact Logmem team for detail .

content is empty!

Email Address

Phone Number

Address